PWL-M200/M300 Magnetostrictive Liquid Level Meter For Oil Depot and Automatic Tank Gauging System

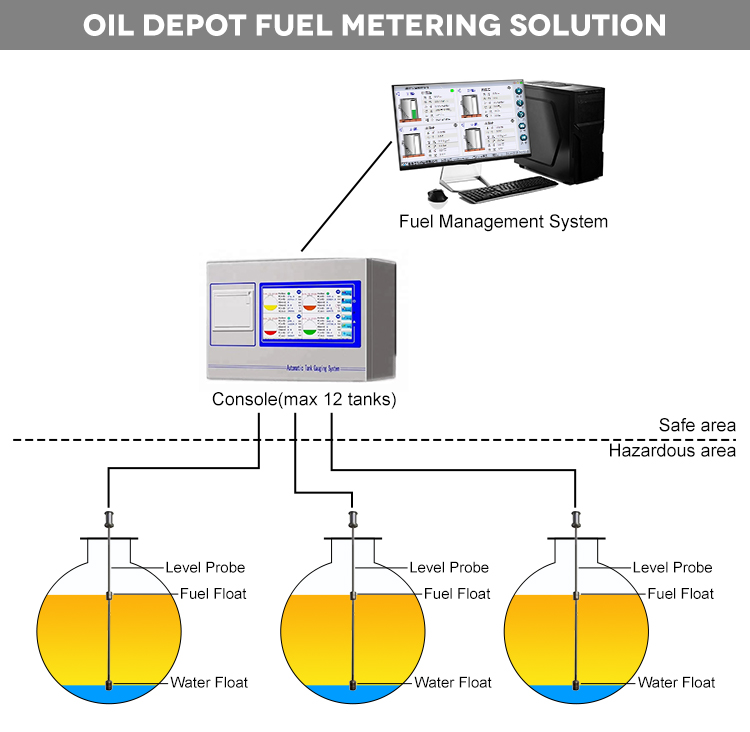

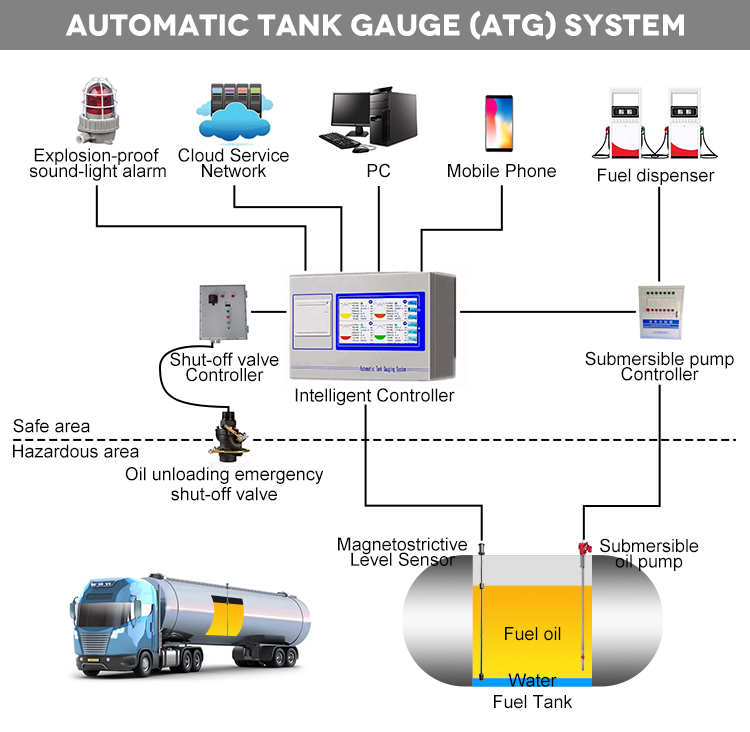

It integrates several parameters for the convenience of fuel management of gas station/oil depot, with just one probe it can output: fuel level, fuel volume, fuel temperature, water level and water volume, high&low fuel level warning in one tank. So to provide reliable and convenience data for tank gauging system. There are different solutions to meet different demands.

Applications:

- Aboveground and underground tanks

- Gasoline, diesel, kerosene, ethanol, water

Features:

-

Industrial design, long service life, fast in running

-

Information is stored in memory for future inquiry

-

With an embedded printer(optional) it can print inventory reports, delivery reports, leak reports and shift report

-

Can monitor up to max 12 tanks and display dynamically the fuel level and water level with colored graphics in proportion

-

After connected with Central Control System through internet, it can provide information for manager to manage the inventory, delivery and the sale of the fuel.

| Specification | |

|

Model |

PWL-M200/M300 |

|

Purpose |

To measure fuel level, water level, volume and temperature in fuel tanks |

|

Mediums |

Gasoline, diesel, kerosene, ethanol, water |

|

Measuring Principle |

Magnetostrictive measuring technology |

|

Measuring Range |

600~15000mm |

|

Accuracy of Level |

±0.3mm/±1.0mm |

|

Accuracy of Temperature |

±0.2℃ |

|

Level Resolution |

0.023mm |

|

Signal Output |

RS485 Modbus RTU |

|

Power Supply |

24~26VDC |

|

Display |

Can be with external console(controller) |

|

Probe Material |

Stainless steel |

|

Floater Material |

2.5” stainless steel floater or φ63mm plastic floater |

|

Working Temp. |

-40~70℃ |

|

Working Pressure |

-0.02MPa~0.6MPa |

|

Blind Area |

200mm fuel, 25mm water (2.5” floater) |

|

Protection Level |

IP67 |

|

Inspection Time |

1s |

|

Installation Method |

Threaded or flanged |

|

Explosion-proof |

Exia II BT4 Ga/Exia II AT4 |